Food processing companies regularly face a variety of challenges unique to their industry. Food must be made safe for consumption on a tight timeline and budget, whether on the factory floor or while being shipped all over the country - or the world.

Food processing companies regularly face a variety of challenges unique to their industry. Food must be made safe for consumption on a tight timeline and budget, whether on the factory floor or while being shipped all over the country - or the world.

Maintaining this consistency has become even harder due to COVID-19, where delays in shipping and distribution can result in food products sitting in warehouses or trucks for a longer time than intended. Meeting the sanitation requirements of the U.S. Food and Drug Administration (FDA) should be a priority for food processing companies, but it can be challenging.

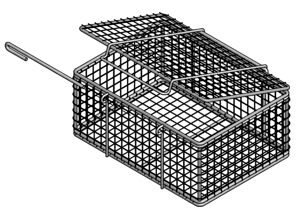

Marlin Steel can help ensure sanitation on the factory floor for food processing. With custom stainless steel baskets designed for food processing tasks, companies can facilitate faster operations with the most thorough sterilization measures.

Sanitation Challenges in the Food Processing Industry

Meeting the requirements of FDA regulations is a particularly big challenge for the food processing industry—one that demands only the most top-notch food processing equipment.

Food processing production facilities must maintain clean environments with no chances of cross-contamination between foods. If sanitation measures are not kept up to FDA standards, then customers can get sick and investigations can result. With the right tools and equipment, food processors can reduce the risk of contamination between foods and bacteria within the facility so products can be shipped to the customer as safely and efficiently as possible.

How Can Custom Wire Baskets Improve Food Processing Sanitation?

Marlin Steel has years of experience in making custom stainless steel baskets for a variety of food processing tasks. Stainless steel is a popular choice for sanitary food handling applications due to its  properties and durability. Find out more about how custom wire baskets can facilitate stringent sanitation conditions during food processing operations.

properties and durability. Find out more about how custom wire baskets can facilitate stringent sanitation conditions during food processing operations.

Durability

Stainless steel baskets that are food-grade are capable of withstanding punishing temperatures that would otherwise melt alternatives, such as plastic. Sanitizing processes commonly involve high-heat methods, and baskets need to be durable enough to be routinely exposed to such high temperatures.

It’s also important to consider the risk of oxidation when using a food-grade stainless steel alloy in high temperatures. Grade 304 stainless steel is often useful for these applications because of its ability to resist oxidation at temperatures of up to 1,697ºF, well over the limit of food processing temperatures.

Certain stainless steel alloys can also handle extremely low temperatures, such as when food needs to be flash-frozen. Martensitic stainless steel is one of the most durable stainless steel alloys when exposed to low temperatures.

Corrosion-resistant & Non-absorbent

Stainless steel is corrosion-resistant, which is an essential quality for equipment in the food processing industry. Besides being resistant to acids, stainless steel baskets can withstand the sterilizing chemicals used in the parts washing process repeatedly so they can be used for years. Stainless steel is also non-absorbent, so there is no concern with cross-contamination.

Electropolishing

One of the most popular finishes for food processing applications, electropolishing creates a smooth, easy-to-clean surface.

Electropolishing is the method of removing the surface material from metal, reducing the surface roughness by leveling out any microscopic peaks and valleys. When food processing baskets and equipment have a rough or uneven surface, that creates small spots where contaminants can hide. This increases the risk that some bacteria may not be fully sterilized or removed when the food processing is cleaned.

By electropolishing stainless steel, these microscopic hiding spots are eliminated, giving contaminants nowhere to hide. This makes it easier to fully ensure electropolished stainless steel equipment is sanitized as thoroughly as possible to prevent any compromise of customer safety.

Pitting-Resistant

Certain food-grade metals may be heat-resistant, but not as durable against salt. Chloride exposures can result in rusting, which can rub off on the food or weaken the basket. So, if a manufacturing process uses a lot of salt, using a “food-safe” metal that is weak to pitting corrosion from exposure to chlorides could result in the metal rusting.

Stainless steel wire baskets made with pitting-resistant metals, such as grade 316 stainless steel alloy are an ideal choice for food processing involving heavy use of salt. This stainless steel alloy has a high resistance to chlorides, such as salt, as well as acids and alkalis.

How Marlin Steel Baskets Can Supply All Your Food Processing Needs

When food processing companies, maintaining sanitary conditions is both a priority and a challenge even before COVID-19. Wire baskets can greatly improve the sanitary conditions of your food processing operations so products can be safe for customers and facilitate greater operational efficiency when there may be delays with distribution.

The experts at Marlin Steel can make the best food-grade metal baskets for all your food-making needs. Marlin’s degreed engineers have years of experience in crafting custom wire baskets to meet different food manufacturing challenges. They can design a basket with the right dimensions and with the right coatings and metals for your applications. For more information and ideas about how to use custom food processing baskets, reach out to the team at Marlin Steel.

.gif)