Marlin Steel’s manufacturing team pride themselves on using the best tool for any given job. With the right piece of factory automation, the manufacture of specific parts and forms is quick, easy, and consistent.

Marlin Steel’s manufacturing team pride themselves on using the best tool for any given job. With the right piece of factory automation, the manufacture of specific parts and forms is quick, easy, and consistent.

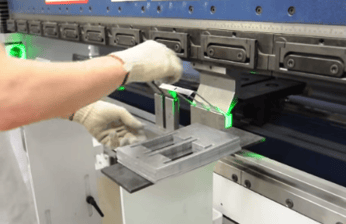

For sheet metal fabrication, one of the most important and useful tools on the Marlin Steel factory floor is the Trumpf CNC steel press brake, a device that can make bends in steel sheet metal with incredible accuracy and consistency.

This piece of equipment is one of Marlin Steel’s secrets to ensuring efficiency in sheet metal fabrication. Here’s why:

Accurate Metal Bending

When it comes to bending steel sheet metal into a custom form for nearly any application, the accuracy of the bend is key. If bends are not made with accuracy, then the final product will simply not work.

Take, for example, a small hard drive housing. Thin layers of perforated sheet metal are commonly used for this type of application to provide a balance between sturdiness and open space to facilitate cooling of the drive. If the angle of a bend is too steep, then the casing won’t fit the drive and it will be rendered useless.

The same applies to custom-bent sheet metal for parts washing and finishing baskets. If the bend isn’t at just the right angle, wit will either not fit the parts being processed, or interfere with the basket’s operation in some way.

The Trumpf CNC press brake makes bends with incredible accuracy, staying with +/- 10 microns of RAM tolerance and a quarter of a degree on every bend in sheet metal forms up to 122” long.

Huge Bending Area

Why bend only the smallest pieces of metal when you could bend one huge one? One of the key benefits of the Trumpf press brake is that it can bend sheet metal all at once along its 122” long bending surface.

Why bend only the smallest pieces of metal when you could bend one huge one? One of the key benefits of the Trumpf press brake is that it can bend sheet metal all at once along its 122” long bending surface.

This allows for the bending of very large sheet metal forms, or the shaping of several smaller identical sheet metal forms at once. Rather than acting as a production bottleneck, the sheet metal bending press brake is the very model of efficiency in production.

To facilitate the bending of metal along such a large area, the Trumpf steel press brake employs 132 tons of mechanical force during each bend, ensuring that even long pieces of sheet metal do not slow down the bending process.

How Marlin’s CNC Press Brake Benefits You

So far, the benefits discussed here have highlighted how Marlin Steel benefits from the use of the CNC press brake. So, how do you benefit from our use of this machine?

First, and foremost, the accuracy of the press brake machine means that you’ll get top-quality bends in your sheet metal forms that will meet your exacting tolerances. This way, there’s less risk of damage to your parts from a poor fit.

Second, the ability of the press brake to handle large objects or multiple smaller ones means more efficient production, reducing Marlin’s time to deliver the custom sheet metal fabrications your company needs to stay on schedule with its own production.

The above benefits translate into fewer part reorders and delays for your company, helping you stay on-schedule and on-budget for whatever you current production project is.

Want to know more about how Marlin Steel can help make your own production process more efficient and cost effective? Check out the link below:

.gif)