Manufacturers, like any business, have a lot to worry about. From upholding environmental and safety regulatory compliance standards, to keeping productivity up, to protecting company IP from theft by competitors, the stream of worries is never-ending.

Manufacturers, like any business, have a lot to worry about. From upholding environmental and safety regulatory compliance standards, to keeping productivity up, to protecting company IP from theft by competitors, the stream of worries is never-ending.

However, few things can keep a manufacturer up at night like the nightmare scenario of a total factory shutdown. Factory shutdowns are the stuff of nightmares for manufacturers because they mean that all productivity, all profitable activity, is completely halted.

There are many potential causes for a factory shutdown, such as an onsite injury and the subsequent investigation into the events surrounding the injury, a lack of basic supplies, power outages, or extensive equipment failure. Unscheduled factory shutdowns impede your ability to meet delivery timetables and fill orders, and can potentially cost you a small fortune in employee labor for little to no return.

So, how can you prevent or minimize the impact of factory shutdown events so that you can rest easy?

Here are a few tips for preventing a total factory shutdown:

Tip #1: Go Above and Beyond in Employee Safety

One of the more common causes of production grinding to a halt is the occurrence of a severe or life-threatening injury on the factory floor. No manufacturer wants to see an employee get injured on the job, so it is important to go above and beyond the minimum standards for employee safety.

One of the more common causes of production grinding to a halt is the occurrence of a severe or life-threatening injury on the factory floor. No manufacturer wants to see an employee get injured on the job, so it is important to go above and beyond the minimum standards for employee safety.

Examples of how you can drastically improve employee safety include:

- Avoid Placing New/Temp Workers in Hazardous Areas without Supervision. Even with great safety implements, there is always a chance for severe injury whenever you have an employee working with hazardous materials or too closely with heavy machinery, especially if said employee is inexperienced. Research cited by investigations.nbcnews.com stated that “temp workers were far more likely to be struck by or caught in machinery in the construction or manufacturing industries.” Unsupervised, new or temporary workers are much more likely to be injured.

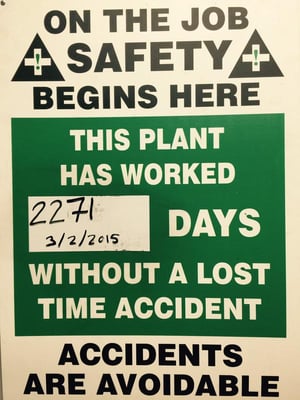

- Using Automated Equipment for Heavy Labor Tasks. For years, Marlin Steel has used automated wire bending robots to handle the task of shaping and cutting lengths of steel wire. Before adopting the use of automated wire bending robots, workers would suffer repetitive motion stress injuries or even accidental amputations while trying to shape wire. Since adopting automated manufacturing equipment and allowing workers to simply set up and supervise the assembly of wire forms, Marlin’s safety record has improved dramatically. In fact, Marlin Steel has gone well over 2,000 days without a time-lost safety incident.

- Establishing Employee Safety Training Programs and Having Employees Complete Follow up Testing. If you do hire temp workers, they should be put through employee safety training programs that are every bit as rigorous as the programs you use for your permanent staff. Reinforcing employee safety training with periodic safety knowledge tests on a yearly or quarterly basis can help improve knowledge of and adherence to safety standards.

By going above and beyond when it comes to employee safety, you can avoid lost-time accidents on your factory floor, and the OSHA investigations that accompany them.

Tip #2: Keep Equipment Well-Maintained

Technology is now an inseparable part of the manufacturing process for top-performing companies. Factory automation helps manufacturers improve safety, quality, and speed of production so that there’s less downtime and more production throughput.

However, while it is true that a machine can work tirelessly for days on end without slowing down or losing quality of work, even the most robust piece of factory automation needs routine maintenance to avoid catastrophic failure.

If allowed to fall into disrepair, manufacturing equipment will lose efficiency and may eventually stop working altogether.

Establishing a regular maintenance schedule where you can have equipment receive maintenance allows you to plan the downtime for important pieces of equipment so that it has a minimal impact on your operations rather than bringing your productivity to a grinding halt.

If possible, find out if you can acquire same-day emergency repair services for your most important pieces of equipment to get broken equipment back into service ASAP.

Tip #3: Build Skills Redundancy in Your Workforce

Picture the following scenario:

Your company is in the middle of a huge specialty order that can make or break your earnings for the quarter, perhaps the year. However, partway through this major push, one of your key employees is hospitalized for an unrelated event such as a car wreck or illness.

It’s bad enough that one of your best employees is hurt, but the news gets worse: this employee was the only person on staff who knew how to set up several key pieces of equipment. Production grinds to a halt as other workers try to figure out how to run the equipment and handle setup tasks.

To keep production rolling smoothly when key personnel become unavailable, consider cross-training your workers so that multiple people can handle key tasks and pieces of equipment. This makes your company more resilient in the face of worker loss.

For more manufacturing industry tips, check out some of our other blog posts, or read the guide at the link below:

.gif)