At the Marlin Steel factory floor, efficiency is the life’s mission of the manufacturing team. Marlin’s clients rely on the Marlin Steel production team to meet strenuous performance parameters and measurement tolerances quickly.

At the Marlin Steel factory floor, efficiency is the life’s mission of the manufacturing team. Marlin’s clients rely on the Marlin Steel production team to meet strenuous performance parameters and measurement tolerances quickly.

Part of making sure that a given custom metal form can meet a client’s strictest standards is performing rigorous stress testing on that product before going into mass production. This applies to wire baskets and trays as well as sheet metal forms.

However, as important as it is to stress test a product before shipping, the old method of manufacturing a part and performing physical tests is woefully insufficient as a means of ensuring performance by today’s standards. The whole process actively impedes modern manufacturing, limiting efficiency and delaying delivery timetables.

Why?

Here are a few of the top reasons why physical prototype stress tests actively limit manufacturing efficiency:

#1: Added Tooling Costs

Tooling costs are a major part of the total cost of manufacturing any custom part. Setting up the robots for a particular custom job and creating any special tools needed takes time and labor, both of which can add to the total cost of the job.

These costs are incurred whether you’re making one part or a hundred parts. So, setting up for a prototype costs just as much as setting up for mass production in many cases.

Worse yet, if the prototype design fails the stress test, the production line may need significant retooling to accommodate any design changes meant to correct for the failure, delaying production and increasing costs even further.

#2: Physical Prototype Testing is Slow

When making a prototype, not only do you have to wait for tooling, you also have to wait for the prototype to be shipped to your factory so that you can run stress tests on it. If ordering from a domestic U.S. company with expedited shipping, this adds at least an extra day to your timetable. If expedited shipping is not available, it could take two weeks for a prototype to arrive once it’s shipped.

When making a prototype, not only do you have to wait for tooling, you also have to wait for the prototype to be shipped to your factory so that you can run stress tests on it. If ordering from a domestic U.S. company with expedited shipping, this adds at least an extra day to your timetable. If expedited shipping is not available, it could take two weeks for a prototype to arrive once it’s shipped.

The delay for an internationally-shipped prototype is weeks at best, months at worst.

Once the prototype arrives, you then have days, weeks, or even months of stress tests to run to thoroughly vet the custom part. The reason for this is some structural issues in a custom metal form might not manifest within the first few dozen uses, which brings us to our next point:

#3: Prototype Tests Might Not Reveal All Issues During Your Initial Testing Period

If you limit your prototype testing time period to just a few days or weeks, long-term issues with the design might not appear during that test phase. This could lead you to greenlight the mass production of custom forms that have an issue that only manifests after 1,000 uses or if left exposed to your process for 15% longer than usual.

If you limit your prototype testing time period to just a few days or weeks, long-term issues with the design might not appear during that test phase. This could lead you to greenlight the mass production of custom forms that have an issue that only manifests after 1,000 uses or if left exposed to your process for 15% longer than usual.

It would be too easy to miss long-term structural integrity problems in a custom wire or sheet metal tray design during a short testing period.

For example, one of Marlin’s clients had, in the past, ordered a large number of cheap steel wire baskets from a competitor because of a low initial cost. However, the basket design failed to account for environmental factors unique to a coastal factory location. While the baskets could stand up to their manufacturing process just fine, long-term exposure to the salty air corroded the baskets, rendering them useless.

Because this process took a long time to become apparent, the problem was missed during the initial prototype testing.

Finding a Better Way to Test Designs

So, if actually making and testing a prototype isn’t the best way to check a custom design for fatal flaws, what is the best way, then?

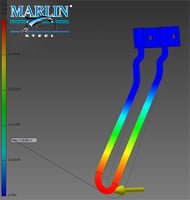

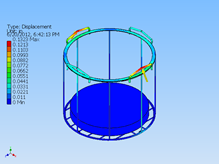

Over the years, Marlin Steel has found that using virtual physics simulation software such as Autodesk is a much more efficient and reliable way to test a new product design than trying to create a prototype.

With Autodesk, a manufacturing engineer can plug in the specifics of the custom part design using an AutoCAD file, then perform thousands of simulated stress tests on the design in mere moments. Parameters such as weight load, temperature, chemical exposure, and time can all be plugged into the simulation to check for how they will affect the final basket design.

For example, an engineer could stipulate the effects of sitting in a salt-rich environment on a basket to see how long it would resist corrosion before failing.

If the part’s design shows that it would experience a deformation as small as the width of a human hair during the simulation, it fails the test. A report is then generated that allows the engineer to why the design failed, giving him or her the information needed to change the design to avoid that failure in the future.

All of this without spending any time, labor, or resources on creating a prototype.

This reduces the testing cycle from something that takes weeks or months into something that can be done in a single day. By doing this, Marlin Steel is able to assure clients an incredibly short time-to-delivery for their custom steel wire form orders.

See how Marlin has helped another client meet tight production schedules by checking out the case study at the link below:

.gif)