The humble stainless steel utility cart should not be overlooked as an essential operational tool. Stainless steel utility carts are a critical tool in many industries to make production operations more efficient.

The humble stainless steel utility cart should not be overlooked as an essential operational tool. Stainless steel utility carts are a critical tool in many industries to make production operations more efficient.

For example, carts with wheels are a daily feature in the food manufacturing industry. In food manufacturing plants, rolling industrial carts provide an optimal solution for moving freshly-prepared products as they cool off.

In the pharmaceutical and medical industries, covered stainless steel utility carts are especially useful for moving medical parts and products while reducing the risk of contamination, or as acting as a mobile cabinet for instruments and equipment.

But, what makes an industrial rolling cart ideal for your production process? What should you look for in such a cart?

The specifics might vary a bit depending on your industry and parts finishing processes used, but some basic qualities to look for in an industrial cart include:

Industrial Rolling Cart Quality 1: Capacity

The basic point of an industrial rolling cart is to make moving large product loads easy. If a cart has too low a capacity, then it won’t be very useful for this purpose, as workers might as well just carry individual trays or baskets between one process and the next.

Heavy duty carts are capable of moving extremely large or heavy parts from one point to another. The capacity of your ideal industrial rolling cart will depend on your industry and what you need the cart for.

Industrial Rolling Cart Quality 2: Ease of Movement

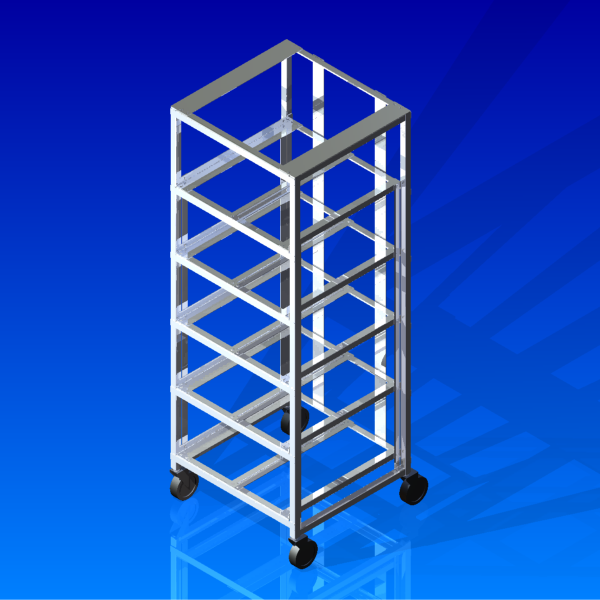

An industrial cart should be easy to move. Carts with wheels are built to easily help facilitate the efficient movement of their loads from one point to another as needed for your production line.

For this purpose, many rolling carts use caster wheels that can freely rotate for ease of movement in multiple directions.

Industrial Rolling Cart Quality 3: Strength/Durability

Every industrial cart should have rugged construction. At least rugged enough to take the weight and stress of a full parts load in your production environment’s toughest conditions.

Every industrial cart should have rugged construction. At least rugged enough to take the weight and stress of a full parts load in your production environment’s toughest conditions.

This is the reason that Marlin Steel typically makes industrial carts out of grade 304 stainless steel or similar materials. Not only does stainless steel provide a high tensile strength, it’s resistant to corrosion caused by exposure to many of the chemicals found in most manufacturing environments.

By using corrosion-resistant steel alloys, heavy duty carts can be made to last for years of intense use, helping to minimize replacement costs over time.

Industrial Rolling Cart Quality 4: Industry-Specific Features

Different industries and different products have their own unique design needs for their rolling carts.

For example, industries with sterile parts requirements might demand that a utility cart be designed to keep dust and dirt from penetrating the interior. Such a cart may use a plastic covering to prevent contaminants from reaching the components in the cart.

Other industries may want to focus on ensuring faster drying of parts after an aqueous or solution-based wash cycle. Here, the utility cart may be designed to maximize open space to allow for greater air flow.

Using a removable covering could provide the best of both worlds to parts that have sanitation requirements at the end of their production process, but need fast drying in between earlier processes.

For industries processing consumable goods, carts additionally need to be designed to prevent the collection of liquids to keep products from becoming contaminated.

Industrial Rolling Cart Quality 5: Ease of Cleaning

From time to time, the stainless steel utility carts themselves may need to be cleaned to maintain compliance with certain industry-specific regulations. In such cases, industrial carts should be designed for ease of cleaning, with no nooks or crannies that are too difficult to sanitize.

These are just a few of the things that companies should check for when looking at industrial rolling carts to use for their production processes. Each industry has their own specific processes and requirements for them. Customizing your own industrial rolling cart allows you to have a cart that fits your exact, unique needs.

Marlin Steel has years of experience in manufacturing custom stainless steel metal forms for different applications, including custom industrial carts. Interested in a custom solution? Reach out to the Marlin Steel team to get started.

.gif)