Manufacturing technology is constantly changing. What was cutting-edge tech a few years ago could be considered almost obsolete today.

Manufacturing technology is constantly changing. What was cutting-edge tech a few years ago could be considered almost obsolete today.

For example, AC resistance welding equipment was once considered the best kind of welding equipment that money could buy. At the time of its introduction, automated AC welding tools were miles ahead of manual welding tools in terms of precision and weld quality.

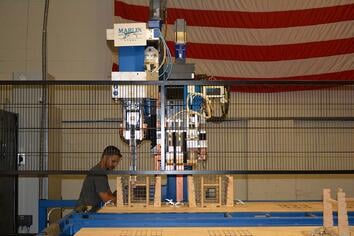

However, AC welding tools are no longer the true top of the line. That title now belongs to MFDC welding equipment such as the IDEAL welder that Marlin acquired last year.

What is MFDC welding, and how does it compare to traditional AC-based welding?

To answer the first question, MFDC stands for Medium Frequency Direct Current, a welding technique that uses power inverters to convert your AC power supply into a DC electrical current for resistance welding.

To answer the second part of the question, here are a few comparisons between AC welding and MFDC welding machine from IDEAL welding systems:

Speed

One of the reasons why automated AC welding was considered such a leap above and beyond manual welding techniques was how much faster the AC welding process was than traditional welding processes.

One of the reasons why automated AC welding was considered such a leap above and beyond manual welding techniques was how much faster the AC welding process was than traditional welding processes.

Where a manual weld would take several seconds or more to complete, an AC weld could be finished in 60/1,000 of a second, limiting stress deformities in the weld.

MFDC welding is even faster than AC welding. With an MFDC welding machine, a weld can be completed in 2/1,000 of a second, roughly 30 times faster than an AC welding machine. This ensures an even higher weld quality with less spatter, blistering, and other deformities in the weld.

Weld Strength and Quality

Another major benefit of automated AC welding over manual welding techniques was a greater level of precision in the weld itself, and a commensurate increase in weld strength and reliability.

Because MFDC welding is so much faster than AC welding, it leaves fewer deformities in the pieces of metal that are being joined. This results in a stronger weld that is better able to meet the rigors of whatever end use you have for the welded metal product.

Additionally, since the weld nuggets left behind by MFDC welding processes are smaller and smoother than AC welding nuggets, there is less need to pass parts through deburring processes to remove sharps and other weld deformities.

Susceptibility to Power Fluctuations

One of the main drawbacks of any automated process, and electrical resistance welding in particular, is the way that power fluctuations affect the equipment. Even when you have a super-stable power grid, there will always be the odd hiccup in the power mains that gives your automated equipment pause.

Because AC welding machines draw the majority of their power directly from your mains, any interruption in the mains has an immediate effect on the operation of your welding equipment, causing welds in progress to be incomplete.

However, MFDC welding tools operate a little differently. Rather than actively draw all of their power straight from your power mains, MFDC welders use a power inverter and capacitors that can store some electrical charge.

So, when there’s an interruption in the power grid and the lights start to flicker, the IDEAL welder can keep operating for a little bit. This means that very minor power fluctuations won’t compromise the quality of your welds.

3D Welding Capabilities

This is an advantage that is unique to the IDEAL welder, rather than to MFDC welding tools in general.

This is an advantage that is unique to the IDEAL welder, rather than to MFDC welding tools in general.

Most traditional AC welding machines can only make welds along a flat plane. If you want to make a weld that goes up and down rather than left and right, you have to either do it manually, or take the work piece off of the welding table and reposition it. Both of these processes take time.

The IDEAL welder, on the other hand, has multiple welding heads that can move along the X, Y, and Z axes, enabling full three-dimensional welds to be fully automated. This saves time and labor on manually adjusting the work piece being welded.

All in all, there’s a lot to recommend the use of MFDC electrical resistance welding tools such as the IDEAL welder over more traditional AC-based welding systems for manufacturing processes. Learn more about Marlin Steel’s MFDC welder from IDEAL welding systems at the link below:

.gif)