Wire forming involves applying force to a length of wire to alter its shape. Raw stock feeds into wire forming machinery either from wire coils weighing anywhere from 5 to 5,000 pounds or as blank forms in a hopper. Forming equipment will then utilize a range of possible techniques such as swaging, bending, shearing, and piercing so that the wire will take on the desired profile. Encompassing a variety of configurations, dimensions, and textures, wire forms are two- or three-dimensional parts of metal wire or tube construction.

Marlin Steel Wire Products LLC is a custom wire form manufacturer designing and engineering products ranging from stainless steel baskets, material handling containers, and racks to swaged and pierced wire forms and S, C, and eye hooks. In business since 1968, our company has extensive experience creating wire form solutions for clients in several industries.

Read on to learn more about our custom wire forming abilities, the materials and finishes we use, the shapes we can achieve, and the advantages of partnering with Marlin Steel.

We do more than stock products. Contact us to see how our customization capabilities can help.

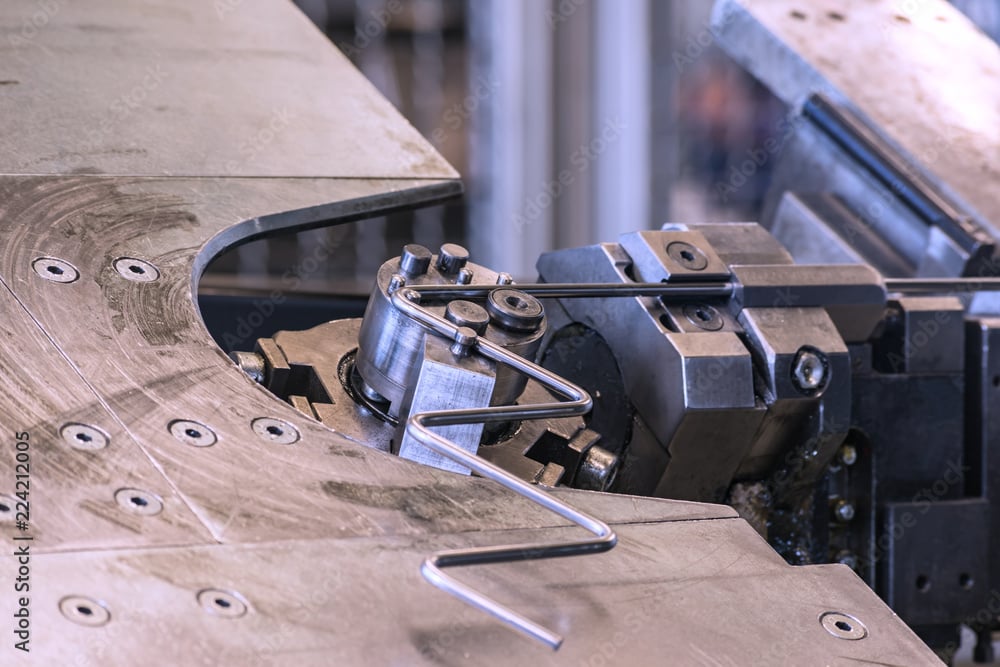

To meet the needs of virtually any industrial or production project, Marlin Steel manufactures all styles of wire forms with precision for fast delivery. We incorporate automated manufacturing equipment and wire-bending robots into our processes to quickly and reliably produce consistent, high-quality results. Our Baltimore shop is equipped with such machinery as:

Each week, we design, manufacture, and ship tens or even hundreds of thousands of custom wire forms to degreed engineers and industrial customers across the globe.

We build our custom creations to your exact specifications. Our team can machine wire with a minimum and maximum diameter of 0.05 and 1.25 inches, respectively, with options for fine and ultra-fine sizes. We'll work closely with you to understand your product needs and then suggest design improvements to optimize your wire form for a truly customized solution.

We utilize a range of materials for our custom metal forms to meet the unique performance needs of your application. We commonly work with:

We offer more than 40 coating and finishing options for our products, with common examples including:

Marlin Steel primarily works with round wire, but other options include:

Over the years, Marlin Steel has created several tons’ worth of custom wire forms. Countless pounds of steel wire have been run through the Marlin Steel production line as hard-working...

Learn More >>

At Marlin Steel, we often stress the importance of our degreed engineers, how they often come up with design suggestions for making your custom wire forms stronger, tougher, and more functional...

Learn More >>

Every wire form has unique challenges. The correct type of machine and properly trained operator skillful at programming can usually tackle them. Discover the challenges in designing and manufacturing steel wire forms.

Learn More >>

At Marlin Steel, our custom wire forming company works tirelessly to find innovative ways to enhance wire form functionality and performance, boost efficiency to accelerate your time to market, and reduce costs. We offer both in-stock and custom products to meet your needs and deadlines. Our team is committed to Quality Engineered Quick®, offering fast delivery on all our 100% Made-in-the-USA products for clients around the world.

In addition to precision wire forming, we also specialize in sheet metal fabrication, steel machining and fixturing, and robotic welding, as well as stress analysis for wire forms with applications in demanding workflows to ensure they'll perform as expected in your manufacturing facility. We're an ISO 9001:2015-certified company, our compliance form for the ASME BTH 1 2008 standard is available upon request, and OSHA has recognized us with their SHARP award for workplace safety.

To learn more about the Marlin Steel difference and our custom wire forming capabilities, contact us today.

Looking for a price estimate or need help as you search for the right wire form for your needs? Submit your custom wire form requirements and a Marlin Steel expert will get back to you with a quote and more information!

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797