In any custom sheet metal basket application, the material your metal basket is made of can be just as important as the design of the basket itself. With the right material, your basket will be able to withstand the stresses of your process for years or decades of use. With the wrong material, a basket will fail early, exposing your workers to potential harm, and your parts/machinery to damage.

In any custom sheet metal basket application, the material your metal basket is made of can be just as important as the design of the basket itself. With the right material, your basket will be able to withstand the stresses of your process for years or decades of use. With the wrong material, a basket will fail early, exposing your workers to potential harm, and your parts/machinery to damage.

One of the most popular materials for sheet metal baskets is stainless steel, as this material possesses a high resistance to corrosion, scaling, and extreme temperatures, as well as having high tensile strength. While stainless steel is a household name, what many people do not realize is just how many different stainless steel alloys are sold today. All told, there are well over 300 different varieties of stainless steel available on the market.

So, which grade of stainless steel is right for your sheet metal basket fabrication? The answer to this question depends on a lot of factors, such as what your basket application is, what chemicals, temperatures, and environments the basket will be exposed to as well as your budget for the baskets and how many you’ll need.

Quick Links:

- Six Different Grades of Stainless Steel

- How to Choose the Best Grade of Stainless Steel For Metal Baskets

- Three Tips for Ordering Custom Sheet Metal Baskets

Six Different Grades of Stainless Steel

There are numerous different grades of stainless steel that can be potentially used for custom sheet metal fabrication. Since each formulation of stainless steel alloy has its own unique properties for melting point, tensile strength, and oxidation and corrosion resistance, it’s important to choose your stainless steel grade based on its application. Some of the more popular grades of stainless steel are listed below:

Grade 304 Stainless Steel

A very common variety of stainless steel, grade 304 is especially noteworthy for its versatility. Its high tensile strength of roughly 621 MPa (90 ksi) is even strong for steel alloys. Like most stainless steel, grade 304 has a high maximum operating temperature (about 870˚C) and is especially chemical resistant. Besides these significant qualities, grade 304 also features temperature and corrosion resistance, making it ideal for numerous applications.

Grade 316 Stainless Steel

Grade 316 stainless steel is another popular grade due to its high tensile strength of 579 MPa (84 ksi) and a maximum use temperature of around 800˚C (1,472˚F). Although it features a lower tensile strength and temperature tolerance than grade 304, grade 316 stainless steel features superior resistance to chlorides, such as salt, than 304 alloy does. This makes it one of the best grades of stainless steel for any application involving exposure to salts and other chlorides.

Grade 330 Stainless Steel

This stainless steel alloy is often preferred for high-temperature environments due to its high-temperature oxidation resistance of up to 1,204˚C (2,200oF). Besides its high oxidation resistance, grade 330 stainless steel also has a high resistance to stress corrosion cracking - making it suitable for environments that alternatives cannot withstand.

Grade 430 Stainless Steel

While it possesses lower tensile strength than grades 304 and 316, with a tensile strength 450 MPa (65 ksi), grade 430 stainless steel is noteworthy for being particularly nitric acid-resistant and is still strong enough for most applications.

Grade 434 Stainless Steel

Grade 434 stainless steel has a tensile strength of 540 MPa (78 ksi) and a maximum operating temperature of 815˚C (1,499˚F), making it stronger than grade 430 and slightly better for high-temperature applications than 316 stainless. Additionally, grade 434 has superior pitting resistance compared to grade 430 stainless steel.

Grade 420 Stainless Steel

While grade 420 is not as chemically resistant as the other grades of stainless steel, it has strong tensile strength and good resistance to mild acids, water, some alkalis, and food compounds, which makes it often used for cutlery. This is often the best grade of stainless steel to use when tensile strength and impact resistance are primary concerns.

How to Choose the Best Grade of Stainless Steel For Metal Baskets

Choosing which stainless steel grades would be the ideal choice for your metal baskets depends on the basket’s application. Depending on the below factors, there are stainless steel grades that will be better suited to withstand your unique application environments. To help you find the right type of stainless steel for your metal sheet basket, here are a few common factors that can influence material choice and which materials might be best for such applications:

Highly Corrosive Chemicals

Many sheet metal basket applications involve the use of caustic materials to clean parts or expunge contaminants. When exposed to heavy corrosives, plain steel tends to corrode very quickly. Different grades of stainless steel, on the other hand, tend to have varying levels of resistance to corrosive chemicals.

The most commonly used grades of stainless steel for applications involving corrosive materials include grade 304 stainless steel and grade 316 stainless steel. Grades 304 and 316 are both austenitic stainless steels, which are among the most common stainless steel alloys on the market.

Grade 304 stainless is a general-purpose alloy, useful for a variety of tasks because of its balance of corrosion resistance, tensile strength, and temperature tolerance. This material is commonly used in immersive wash processes where the basket may be submerged for prolonged periods of time.

For especially caustic applications, such as ones involving food, biomedical, and marine applications, grade 316 stainless steel is even better than grade 304 stainless steel for resisting pitting and corrosion and has an even higher tensile strength. This steel alloy features more nickel and molybdenum content than grade 304 does, which tends to make grade 316 steel more expensive than grade 304.

Operating Temperatures

Many processes, such as parts sterilization or heat treating, tend to employ extreme temperatures to get parts finished. While effective for eliminating biological contaminants and the like, high-temperature processes tend to put a lot of stress on a basket.

Many different types of stainless steel tend to have a very high-temperature tolerance, which is what makes them superior to plastic baskets for high-temperature applications. While steel alloys can take up to 1600° F, plastics can typically only survive exposure to temperatures in the 200-300° F range. The right stainless steel grades can withstand environments that alternatives cannot.

An example of a stainless steel alloy that would be ideal for extreme-temperature applications would be grade 330SS. This material can withstand temperatures up to 1900° F (940° C) while retaining its tensile strength. This prevents the basket from becoming deformed through heat stress or the weight of held parts, even as your finishing process reaches peak temperature. Grade 330 stainless steel is typically more cost-effective than Inconel for high-temperature applications, but is more expensive than grade 316SS.

Delivery Time

When you’re making a basket order, chances are that you have a use for that basket either now or in the immediate future. You naturally want your basket order to be filled ASAP, but how does your choice of basket material affect your delivery time?

To put it simply, most manufacturers typically stock only the most commonly-ordered materials, such as grade 304 and 316 stainless steel. Other, more uncommon grades of stainless steel have to be specially-ordered by the manufacturer, who then has to wait on the shipping of the raw material to begin work on your order.

The amount of delay caused by ordering a rarer material is a bit random, as it depends on the manufacturer’s supplier and how quickly and reliably they can ship material. If you need a stainless steel basket immediately, then common grades of stainless steel will be your best choice.

Three Tips for Ordering Custom Sheet Metal Baskets

When ordering custom sheet metal baskets, there are several factors to consider to help you receive the best quality basket customized for your unique specifications.

Choose American-Made Stainless Steel

/MUST%20CREDIT%20WITH%20THE%20FOLLOWING_Photo%20by%20David%20Bohrer%20%20National%20Assoc.%20of%20Manufacturers_DB13885.jpg?width=300&name=MUST%20CREDIT%20WITH%20THE%20FOLLOWING_Photo%20by%20David%20Bohrer%20%20National%20Assoc.%20of%20Manufacturers_DB13885.jpg) Besides helping to support the American economy, there are numerous benefits for selecting American-made steel for your custom baskets. You can depend on the reliability of American-made parts. While foreign-made baskets are generally cheaply made, American baskets can meet incredibly tight parts tolerances and must meet American safety standards so they are safe and effective for your manufacturing applications.

Besides helping to support the American economy, there are numerous benefits for selecting American-made steel for your custom baskets. You can depend on the reliability of American-made parts. While foreign-made baskets are generally cheaply made, American baskets can meet incredibly tight parts tolerances and must meet American safety standards so they are safe and effective for your manufacturing applications.

Additionally, there is no need for American companies to wait for slow overseas shipping or customs with an American stainless steel custom wire basket. As soon as the metal basket is finished, it can be put out on a priority shipping truck for immediate delivery while foreign baskets could take months to be prepared and shipped out.

Ask the Right Questions

Different companies will have different needs, so customized baskets will look different for an automotive manufacturer than one made for seafood harvesting and processing. By asking the right questions, your custom metal basket can be designed to meet your unique needs specifically and improve quality, consistency, and manufacturing throughput.

However, which questions are the right ones to ask when building a custom metal basket fabrication? The ones in the custom basket questionnaire form are a good start to help understand the specifics you need to make a custom metal basket.

Test Basket Designs

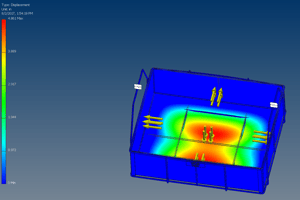

When designing a custom basket for your application, make sure you order from a manufacturer where a design engineer can make a list of desirable materials and ones that are acceptable for the application based on the process the basket will be exposed to.

Marlin Steel’s degreed engineers, for example, use Autodesk software to test basket designs to see if the material of the basket will stand up to a given process throughout thousands of uses. This way, it is possible to determine if a given material will be enough to meet your needs without having to go to the time-consuming expense of making dozens of prototype baskets and testing them on-site. The benefit of doing this is that it allows you to reliably find the most cost-effective material for your application to fit your budget.

So, which grade of stainless steel is right for your basket application? If you still don’t know the best grade of stainless steel for your application, or have any questions about Marlin’s customized metal baskets, then contact Marlin Steel’s experienced, degreed mechanical engineers to find out!

.gif)