Using virtual testing software such as Autodesk to vet basket designs, Marlin Steel engineers eliminate the time-consuming process of making endless prototypes that wouldn’t work, saving time and money.

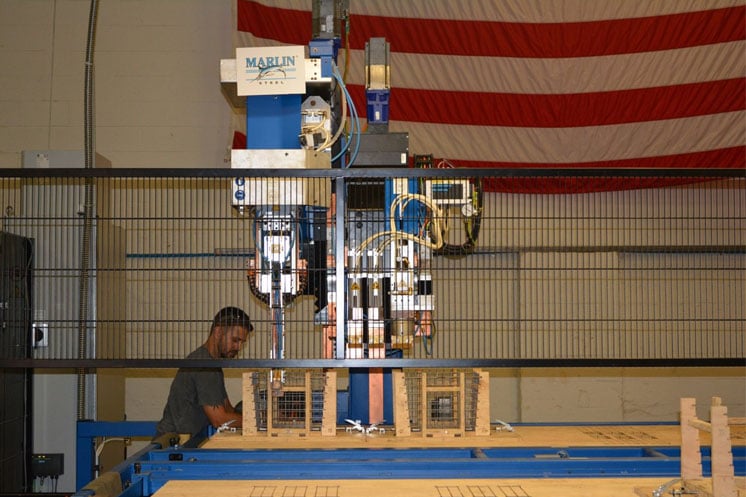

Marlin Steel can build wire baskets very quickly and with consistency that manual labor simply can’t match effectively. They can be custom designed to suit your specific need. These robots assemble wire forms morning, noon, and night without getting tired. This allows for not only fast production of your baskets, but ensures that each basket meets your tolerances, from the first to the last.

Request Information“Fast Delivery, Incredible Quality”

Anything you need can be precision-manufactured with rapid delivery thanks to the speed and consistency of our automated manufacturing equipment. Any style of metal basket can be engineered to meet your specific needs. There are a wide range of finishes and coatings that our mechanical engineers will help you select.

Application Features:

By employing advanced factory automation, including:

Marlin Steel crafts unique custom basket designs for clients in many different industries all across the globe. Clients in the automotive and aerospace industries rely on Marlin Steel’s factory automation know-how and tools to manufacture custom metal forms to exacting tolerances.

Businesses both large and small count on the knowledge of Marlin Steel mechanical engineers to perfect every aspect of their custom wire basket’s design, from the shape of the basket to the materials used in it. With the right materials, your baskets will last you for years or decades so that you only have to pay for them once instead of having to waste money year after year on reorders.

Looking for a quote or trying to determine which type of wire basket is the best fit for you? Our wire baskets are custom designed to suit your specific needs! Reach out to one of our experts to discuss your options today.

Marlin Steel specializes in manufacturing metal forms including stainless steel parts, S-hooks, racks, washing baskets, and sheet metal material ...

Read More

Cotter pins are a common tool for fastening objects that you may need to quickly disassemble later. In pharmaceutical and healthcare applications, ...

Read More

Medical and pharmaceutical product manufacturers and users both have to be very careful about how they store and wash their tools. Manufacturers need ...

Read More

Wire Basket 960008

Wire Basket 960008

Round Ultrasonic Cleaning Basket 980001

Round Ultrasonic Cleaning Basket 980001

Wire Basket with Handles 980002

Wire Basket with Handles 980002

Wire Basket 997001

Wire Basket 997001

Wire Basket with Handles 1038001

Wire Basket with Handles 1038001

Wire Basket 1043001

Wire Basket 1043001

Wire Basket with Handles 1045001

Wire Basket with Handles 1045001

Wire Basket 1051001

Wire Basket 1051001

Reach out to Marlin Steel today to help meet all of your custom wire product needs.

Using virtual testing software such as Autodesk to vet basket designs, Marlin Steel engineers eliminate the time-consuming process of making endless prototypes that wouldn’t work, saving time and money.

By employing advanced factory automation, including:

Marlin Steel can build wire baskets very quickly and with consistency that manual labor simply can’t match effectively. They can be custom designed to suit your specific need. These robots assemble wire forms morning, noon, and night without getting tired. This allows for not only fast production of your baskets, but ensures that each basket meets your tolerances, from the first to the last.

Marlin Steel crafts unique custom basket designs for clients in many different industries all across the globe. Clients in the automotive and aerospace industries rely on Marlin Steel’s factory automation know-how and tools to manufacture custom metal forms to exacting tolerances.

Businesses both large and small count on the knowledge of Marlin Steel mechanical engineers to perfect every aspect of their custom wire basket’s design, from the shape of the basket to the materials used in it. With the right materials, your baskets will last you for years or decades so that you only have to pay for them once instead of having to waste money year after year on reorders.

Anything you need can be precision-manufactured with rapid delivery thanks to the speed and consistency of our automated manufacturing equipment. Any style of metal basket can be engineered to meet your specific needs. There are a wide range of finishes and coatings that our mechanical engineers will help you select.

Looking for a quote or trying to determine which type of wire basket is the best fit for you? Our wire baskets are custom designed to suit your specific needs! Reach out to one of our experts to discuss your options today.

Ultrasonic cleaning for parts plays an important role for many of today’s manufacturers. It saves them time and money, and compared to manual ...

Read More

Aircraft maintenance, repair, and overhaul is a vital component within the aerospace industry. After all, in aerospace, the margin of error is ...

Read More

One of the reasons stainless steel is used in so many industries is its versatility. The properties that make it valuable in one field, like food ...

Read More

Translate This Page

Marlin Steel Wire Products

2648 Merchant Drive

Baltimore, MD 21230-3307

Phone (410) 644-7456

Fax (410) 630-7797